During the 1800s straw plaiting provided paid employment for tens of thousands of men, women and children from Cornwall to the Orkney and Shetlands. For a variety of reasons by the 1930s straw plaiting had become almost forgotten. It is now listed as a Critically Endangered Craft on the Heritage Crafts Red List of Endangered Crafts.

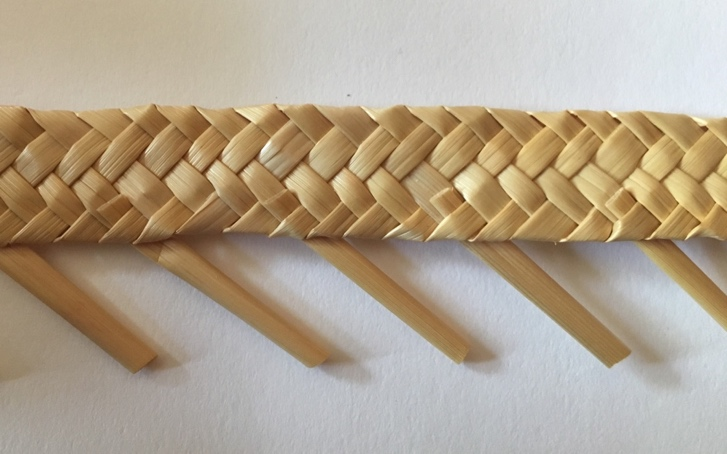

Straw plait is made as a long length suitable for making into hats, bags or baskets. Instead of using the whole length of the straw stem hat plait is made from short lengths that have been matched for thickness. This means regular joining has to be part of the making process.

The straw plait was made for money so had to be perfect, any imperfections or unevenness of its width would result in a lower price. At worst it might mean the plaiter could not sell their work and the family might go hungry. This is why the plait had to be made using short lengths of straw.

The straw plaiter worked as part of a much larger organisation. After harvest the straw was cleaned, cut into short length, graded through sorters and made into bundles of evenly matched straws. The plaiter would purchase these bundles and begin their work.

Plait is traditionally made from whole straws also known as pipes or from split straws. Traditionally the straw was bleached with sulfur which lightened the colour and softened the straws making them easier to plait.

If the plaiter was making split straw plait, then the first job was to make the splints. The whole straws were split using a splitter, then milled to soften them. Many of the plaits were made using dyed straws to create a range of colourways.

Before working the plaiter either dipped the splints into water or passed them through their mouths to moisten them. Whole straws were dipped into water. The damped straws were wrapped in a cloth or paper and placed under the left-arm, so each pipe or splint could be drawn out with the right hand and added to the plait.

Working to instruction of what plait pattern to make and how much to make, the plaiter would work away. Once a length of 10 or 20 yards (9 or 18 metres) of plait was made, the joined ends were clipped off. Next the plait was milled and wound into a piece or hank.

On market day the plaiter gathered up the plait, usually wrapped it in a large cloth and took it to market. This could sometimes involve a walk of many miles. To make certain of a good price they had to be there ready for the market bell to ring, often at 9am, and for the buying to begin.

In the villages known for producing high quality plait, the Plait Dealers would go to the village and buy directly from the plaiters. The Plait Dealers would also provide them with the straws and with orders for the next week’s work.

Did you know?

The word plait was originally spelled as plat or platt. It is pronounced pl-at, as in cat, not pl-8 as in plate.

In the hat industry the word straw covered a wide range of materials not just wheat straw. One of the earliest types of straw used to make hats was actually wood chip.

The four and five- end spiral plait used to make corn dollies was first made for decorating hats and for making baskets. It was an important product made in Italy from the 1700s into the mid-1900s.

The flat plait used to make a Glory Braid started its life as part of the Italian hat industry. It was made using very fine Italian straws and often made with natural and coloured straws, so a pattern was created. This plait wasn’t just made using 12 straws, it was also made with 16 or even 22 ends of straw.

A version of the raised diamond plait is another of the many we use in Decorative Straw Work that originated in the Italian hat industry in the 1880s.